Understanding the Parts of Hydraulic Pumps for Business Efficiency

In today's fast-paced industrial environment, hydraulic pumps play an essential role in powering various machinery within the automotive and motorcycle sectors. Whether you run a large manufacturing facility or a small repair shop, understanding the parts of hydraulic pumps and their functions can greatly enhance your operational efficiency. In this comprehensive guide, we will delve into the intricate details of hydraulic pumps, exploring each component and its significance in maintaining the productivity of your business.

The Basics of Hydraulic Pumps

A hydraulic pump converts mechanical energy into hydraulic energy, enabling the utilization of fluid power to perform work. This transformation is achieved through various ≤components, each meticulously designed to fulfill key roles in the hydraulic system. A basic understanding of these components is beneficial for anyone involved in the auto parts and supplies business.

Main Components of a Hydraulic Pump

Hydraulic pumps are comprised of several crucial parts that work together harmoniously. The understanding of these parts allows technicians and business owners to maintain and repair hydraulic systems effectively. Below are the primary components:

- Pump Housing: This is the outer shell of the pump, designed to contain the other components and fluids. It is typically made from durable materials to withstand high pressures.

- Pump Shaft: The shaft connects the pump to the motor, transferring rotational energy and driving the pump’s operation.

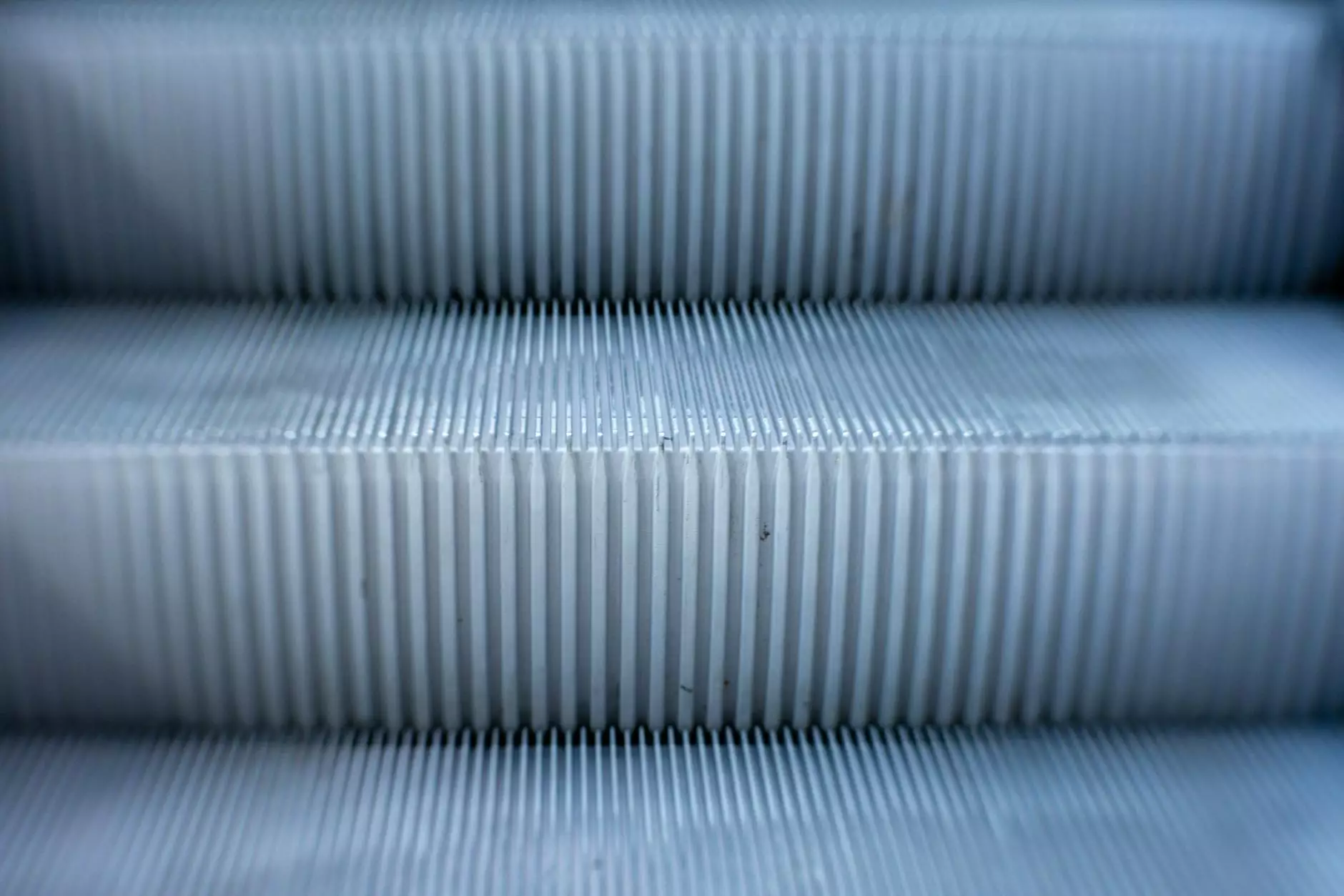

- Gear Set: In gear pumps, the gear set consists of two gears that mesh together to create a void that draws fluid into the pump and pushes it out under pressure.

- Rotors: In rotary pumps, the rotor turns within a housing, generating flow and pressure through centrifugal force.

- Seals and O-Rings: Essential for preventing leaks within the pump, seals and O-rings ensure that the hydraulic fluid remains contained and operates efficiently.

- Check Valves: These are used to prevent backflow in the system, ensuring the fluid only moves in the intended direction.

- Return Filter: As hydraulic fluid circulates, contaminants may enter the system. The return filter cleans the fluid before it re-enters the pump, ensuring longevity and efficiency.

- Control Valve: This component regulates the flow and pressure of the hydraulic fluid, allowing for precise control in various applications.

How Hydraulic Pumps Work

Understanding the operation of hydraulic pumps is crucial for optimizing their performance. The basic working principle is based on Pascal's Law, which states that pressure applied to a confined fluid is transmitted undiminished in every direction. Here's a step-by-step explanation:

- Activation: When the pump shaft is rotated by the motor, the internal components are set into motion.

- Fluid Intake: The movement creates a low-pressure area within the pump, drawing hydraulic fluid from the reservoir.

- Pressurization: The design of the pump's internal components compresses the fluid, significantly increasing its pressure.

- Discharge: The high-pressure fluid is then forced out of the pump through the discharge port, ready to perform work in the hydraulic system.

Importance of Hydraulic Pumps in the Automotive Industry

Hydraulic pumps are indispensable in auto parts and supplies, particularly in applications such as:

- Power Steering Systems: Hydraulic pumps enable drivers to steer their vehicles with minimal effort, enhancing safety and control.

- Brake Systems: Hydraulic pressure is vital for delivering the force needed to operate braking systems effectively.

- Transmission Systems: Hydraulic pumps facilitate the automatic shifting of gears, improving performance and efficiency.

- Suspension Systems: They enable the adjustment of vehicle suspension, adapting to various driving conditions for improved ride quality.

Key Benefits of Maintaining Hydraulic Pumps

Regular maintenance of hydraulic pumps is critical for ensuring durability and performance. Here are some key benefits:

- Increased Lifespan: Regular checks and maintenance can prevent premature wear and tear, prolonging the life of the pump.

- Optimized Performance: Proper maintenance ensures that hydraulic pumps operate at peak efficiency, reducing downtime and operational costs.

- Safety Enhancements: Well-maintained hydraulic systems reduce the risk of failures or accidents, creating a safer work environment.

- Cost Efficiency: Investing in maintenance reduces the need for costly repairs and operational interruptions.

Common Issues with Hydraulic Pumps

Despite their robust design, hydraulic pumps can encounter several issues. Understanding these problems is essential for timely and effective troubleshooting:

- Leakage: Often caused by worn seals or O-rings, leakage can lead to reduced efficiency and increased operational costs.

- Noisy Operation: Unusual noises often indicate issues such as cavitation or poor lubrication, requiring immediate attention.

- Overheating: Excessive heat can damage components and fluids. Proper ventilation and coolant can help avoid this issue.

- Reduced Efficiency: A drop in performance may arise from clogged filters or internal wear, necessitating regular checks.

Conclusion

In summary, a thorough understanding of the parts of hydraulic pumps and their functionalities is vital for anyone engaged in the automotive and motorcycle industries. Regular maintenance and prompt troubleshooting can enhance operational efficiency, prolong equipment life, and ensure safety in all business operations.

By equipping yourself with knowledge about hydraulic pumps and the components within, you are undoubtedly preparing your business for greater success. At Shop Hydraulic America, we specialize in high-quality hydraulic parts and supplies to meet your needs. Our extensive inventory ensures that you find all the essential components to keep your operations running smoothly, whether it’s for automotive or motorcycle applications.

For more information about our products or to explore our offerings in Auto Parts & Supplies and Motorcycle Parts & Supplies, visit us at shophydraulicamerica.com.