Exploring the Innovations of Aluminum Case Makers

In the world of aluminum case makers, a revolution is quietly unfolding. These skilled artisans and manufacturers are not merely creating cases; they are engineering solutions that offer superior protection, lightweight design, and bespoke customization. With the rise of global shipping, technology, and personal mobility, the demand for custom aluminum cases has surged, making it essential to explore what distinguishes top players in this sector, especially MSAcase.

The Significance of Aluminum Case Makers

Why should we focus on aluminum case makers? The answer is multi-faceted:

- Durability: Aluminum cases are renowned for their strength and resistance to wear and tear.

- Lightweight: Compared to many other materials, aluminum provides a lighter alternative without compromising strength.

- Aesthetic Appeal: The sleek metallic finish of aluminum cases offers a high-end look that enhances product presentation.

- Customization: Manufacturers like MSAcase allow clients to personalize their cases to fit specific needs.

The MSAcase Advantage

Innovative Manufacturing Techniques

At MSAcase, we pride ourselves on using cutting-edge technology and innovative manufacturing processes. Our methods include:

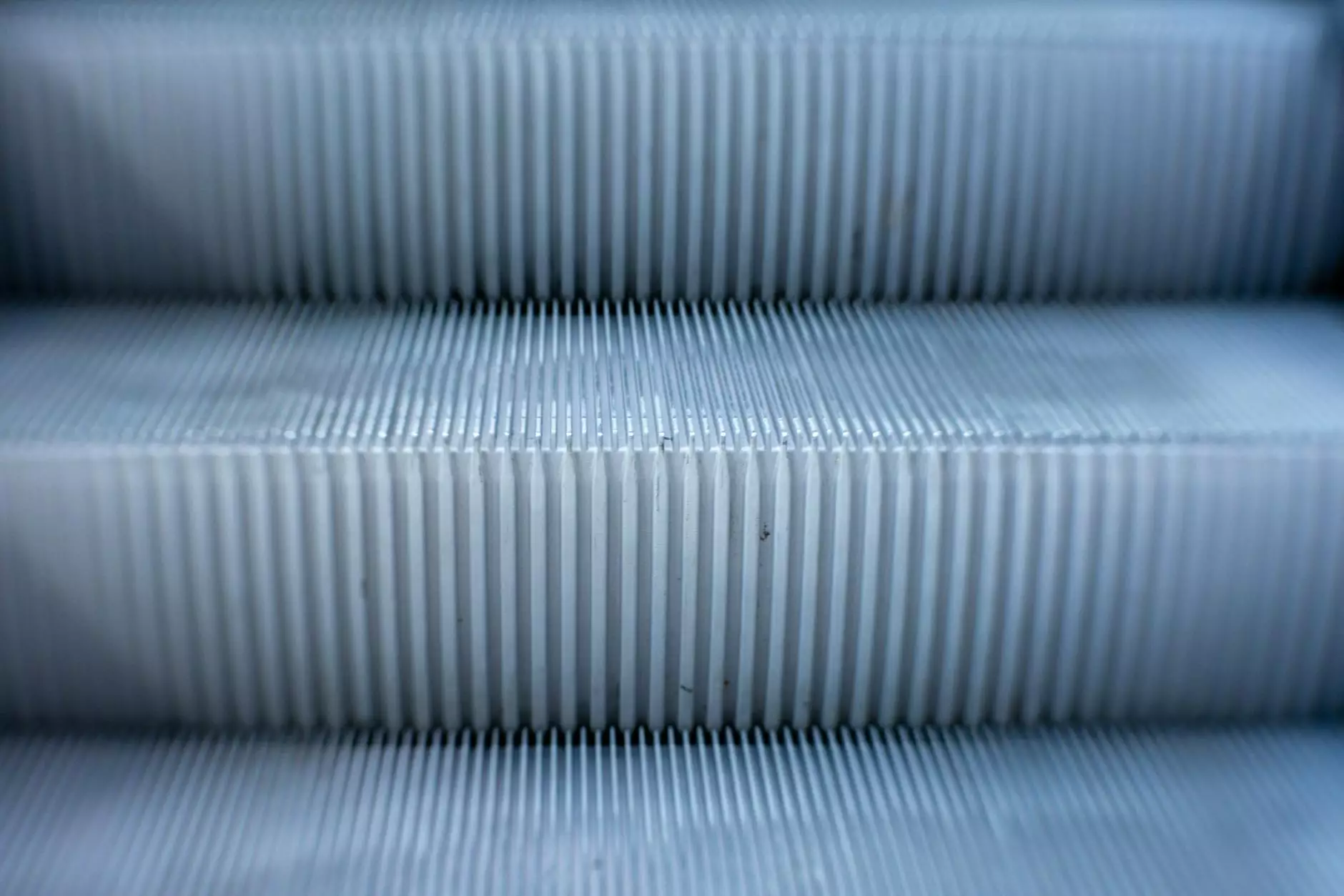

- CNC Machining: This process ensures precision and consistency across batches, maintaining a high standard of quality.

- Robot-Assisted Assembly: Automation in assembly not only speeds up production but also reduces human error, leading to superior products.

- Advanced Coating Techniques: The integration of protective coatings helps prevent scratches and enhances longevity.

Commitment to Customization

One of the standout features of MSAcase is our commitment to customization. Businesses often require unique specifications for their cases. Whether it's for:

- Transporting high-value equipment

- Exhibiting products at trade shows

- Protecting sensitive electronics

Our team works closely with clients to ensure that every case meets their exact requirements, from dimensions and internal configurations to external branding and color schemes.

Applications of Aluminum Cases

The versatility of aluminum cases is evident in their various applications across different industries:

1. Electronics Industry

For manufacturers of sensitive equipment, aluminum cases provide the perfect balance of protection and portability. Custom foam inserts can be tailored to keep devices securely in place during transit.

2. Medical Field

Aluminum cases are frequently used to transport medical devices and equipment. The protective qualities of aluminum ensure that vital machinery is safe from fluctuations in temperature and physical shocks.

3. Aerospace and Defense

In high-stakes environments like aerospace and military operations, aluminum cases are often a preferred choice due to their rugged build and ability to endure extreme conditions.

4. Musical Instruments

Musicians depend on durable cases to protect their instruments while traveling. Aluminum cases offer a classy aesthetic while ensuring the instruments are secure and protected.

The Future of Aluminum Case Manufacturing

Sustainability in Production

As global concern for the environment grows, MSAcase is committed to implementing sustainable practices in our production processes. Aluminum is a highly recyclable material, and we strive to minimize waste during manufacturing. Our goal is to lead the charge in sustainable practices within the aluminum casing industry.

Integration of Smart Technology

The future is looking towards technology integration. Imagine aluminum cases equipped with smart sensors to monitor environmental conditions, GPS for tracking, and alerts for unauthorized access. MSAcase is already researching these possibilities to stay at the forefront of innovation.

How to Choose the Right Aluminum Case Maker

When seeking a reliable aluminum case maker, consider the following criteria:

- Experience: Look for manufacturers with a proven track record in the industry.

- Customization Options: Ensure they offer a wide range of customization to meet your specific needs.

- Quality Assurance: Investigate their quality control processes to guarantee product reliability.

- Client Reviews: Read testimonials and reviews to gauge customer satisfaction.

Conclusion

As we continue to forge ahead into a technologically advanced and fast-paced world, the role of aluminum case makers becomes ever more critical. With manufacturers like MSAcase at the forefront, customers can expect innovations that not only meet but exceed their expectations. Whether you need robust protection for valuable equipment or stylish solutions for showcasing products, the exceptional capabilities of aluminum cases make them the ultimate choice. Together, let’s embrace the future of protection and customization!